Automatic high speed nail making machine

Our automatic high-speed nail making machine is built for precision, speed, and stability.

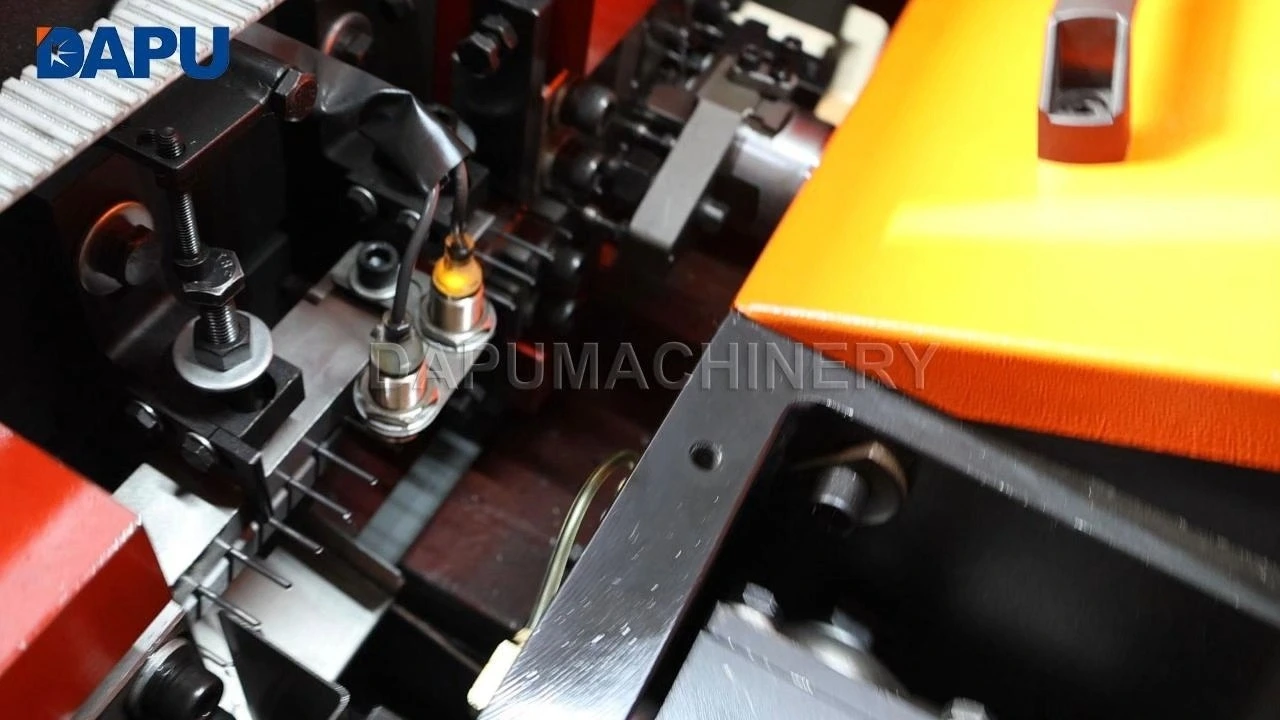

It completely eliminates issues like inconsistent nail lengths, off-center heads, and poor head-to-shank ratios. Powered by advanced Delta PLC control, it ensures error-free operation. The system integrates Schneider low-voltage components for stable, durable performance, even in demanding environments.With Inovance modular inverters and Type-C debugging, setup time is reduced by up to 67%, delivering faster deployment and greater safety. The newly designed nail conveyor system offers quieter, faster output with easy maintenance — making this machine the ideal choice for efficient, trouble-free nail production.

Technical Parameter

| Model | DP-ZDJ-L50 | DP-ZDJ-L90 | DP-ZDJ-L100 | DP-ZDJ-L130 | DP-ZDJ-L150 |

| Wire diameter [mm] | 1.8-2.5 | 2.0-3.5 | 2.0-3.8 | SS: 2.5-4.8 Low carbon: 2.5-5.2 |

SS: 2.5-4.8 Low carbon: 2.5-5.5 |

| Nail length [mm] | 32-64 | 32-92 | 40-100 | 50-130 | 70-150 |

| Speed [pcs/min] | 800 | 760 | 860 | 650 | 500 |

| Motor | 5.5kW + 1.5kW | 5.5kW + 2.2kW | 5.5kW + 1.5kW | 7.5kW + 2.2kW | 11kW + 2.2kW |

| Dimension [mm] | 1500×950×1300 1600×900×1650 420×760×970 |

1500×1180×1100 1600×900×1650 420×760×970 |

1650×1250×1300 1600×900×1650 420×760×970 |

1540×1160×1300 1600×900×1650 420×760×970 |

1650×1200×1300 1600×900×1650 420×760×970 |

| Weight [kg] | 2500 | 2800 | 3000 | 4200 | 4500 |

| The listed technical parameters are standard; machines can be customized according to customer requirements. | |||||

| Items | Brands |

| PLC | Delta |

| Automatic air switch | Schneider |

| Switching power supply | Schneider |

| Inverter | Inovance |

| Touch screen | Delta |

| Intermediate relay | Schneider |

| Proximity switch | Omron |

DAPU Fully automatic high speed nail making machine Core technology

● Our nail caps have good stability, double molds and double punches, and two moldings. The machine is equipped with long and short nail sensor, automatic turning machine function, no waste, which ensures the quality of nail making.

● The cost of abrasive tools is low, and a pair of scissors can generally use 100 tons of nails;

● Cost-effective, easy to operate, easy to change specifications;

● Raw materials: black wire, bright wire

● The machine has high stability, and the speed can reach 760 pieces/minute; it can save a lot of labor and increase production capacity (the production capacity can be more than doubled under the same site and manual work).

● Fast delivery, ready for immediate production

● Supports bulk orders and continuous production needs

● OEM / ODM support tailored to your brand or market

● Ideal for distributors, manufacturers, and hardware wholesalers

● Proven technology used in 100+ countries with reliable technical support

Finished product

Our Cases - what we finished

So far, we have cooperated with companies from over 200 countries. Although these companies come from different industries and regions, they choose to work with us for the same reason: we offer high-quality products and services at more competitive prices. In addition, DAPU is the most reputable and experienced manufacturer of automatic mesh welding machines in China.

FAQ

What we do

It is your support that enables us to focus more on wire mesh machinery. Your feedback on each problem is the advantage of our next product. We can only report to every customer with our wholehearted service. Every purchase of a machine is the beginning of our cooperation and the starting point of your efficiency and reform. Let us witness our success.

Our expanded metal Machine production lines

In order to meet the customized needs of more of our customers for expanded metal and the production needs of expanded metal machines, we have comprehensively considered all market factors and put a lot of effort into the expanded metal production line.

Our team

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.