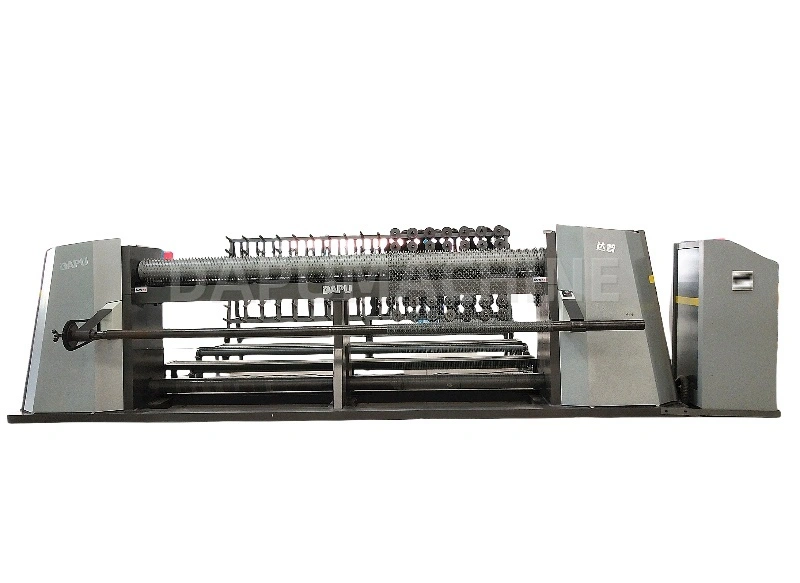

High-Speed Hexagonal Wire Mesh Machine for Chicken Wire & Gabion Production – DAPU Manufacturer

The DAPU Hexagonal Wire Mesh Machine is designed for efficient, high-speed production of chicken wire and gabion mesh. Equipped with PLC, Schneider components, and four servo motors, it ensures smooth operation, low noise, and easy control. Features like automatic stop on wire break, oil lubrication, and triple-roll weaving boost productivity and reduce downtime. Ideal for expanding production with reliable performance and customizable solutions.

Technical Parameter

|

Model |

DP-CSR-4000 |

|

Wire diameter |

1.2-2.4 mm |

|

Mesh opening size |

92×114 mm (one machine only makes one size) |

|

Mesh width |

Max. 4000 mm |

|

Weaving speed |

90–100 m/h |

|

Motor capacity |

2.3 kW + 2.3 kW + 2.3 kW + 4.4 kW |

|

Number of Twists |

6 |

|

Machine Weight |

3.8 T |

|

Machine Size |

4×4.5×1.8 m |

|

The listed technical parameter is standard; it can be customized according to customer requirements. |

|

DAPU cnc Hexagonal Wire Mesh Machine Core technology

● The Hexagonal Wire Mesh Machine is easy to operate, equipped with a reliable PLC control system and touch screen interface for smooth and intelligent operation.

● Designed with a compact vertical structure, this machine takes up minimal floor space—perfect for factories with limited space. Its upward expansion helps save factory rent and makes it easier to integrate into existing production line layouts.

● The mesh surface is flatter and more uniform. Thanks to the vertical weaving design, the mesh's gravity direction is perpendicular to the weaving direction, ensuring consistent tension and better mesh quality.

● Powered by four high-precision servo motors, this Hexagonal Wire Mesh Machine offers fast, stable, and quiet operation. It controls the thorn, brace, dislocation, and board with much higher performance than traditional mechanical transmission systems.

● An automatic oiling device keeps chains, gears, spindles, and other critical components fully lubricated. This reduces wear, minimizes manual maintenance, eliminates the need for frequent manual oiling, and significantly cuts down on downtime and manual errors—extending the overall lifespan of the equipment.

Finished product

Our Cases - what we finished

So far, we have cooperated with companies from over 200 countries. Although these companies come from different industries and regions, they choose to work with us for the same reason: we offer high-quality products and services at more competitive prices. In addition, DAPU is the most reputable and experienced manufacturer of automatic mesh welding machines in China.

FAQ

What we do

It is your support that enables us to focus more on wire mesh machinery. Your feedback on each problem is the advantage of our next product. We can only report to every customer with our wholehearted service. Every purchase of a machine is the beginning of our cooperation and the starting point of your efficiency and reform. Let us witness our success.

Our expanded metal Machine production lines

In order to meet the customized needs of more of our customers for expanded metal and the production needs of expanded metal machines, we have comprehensively considered all market factors and put a lot of effort into the expanded metal production line.

Our team

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.