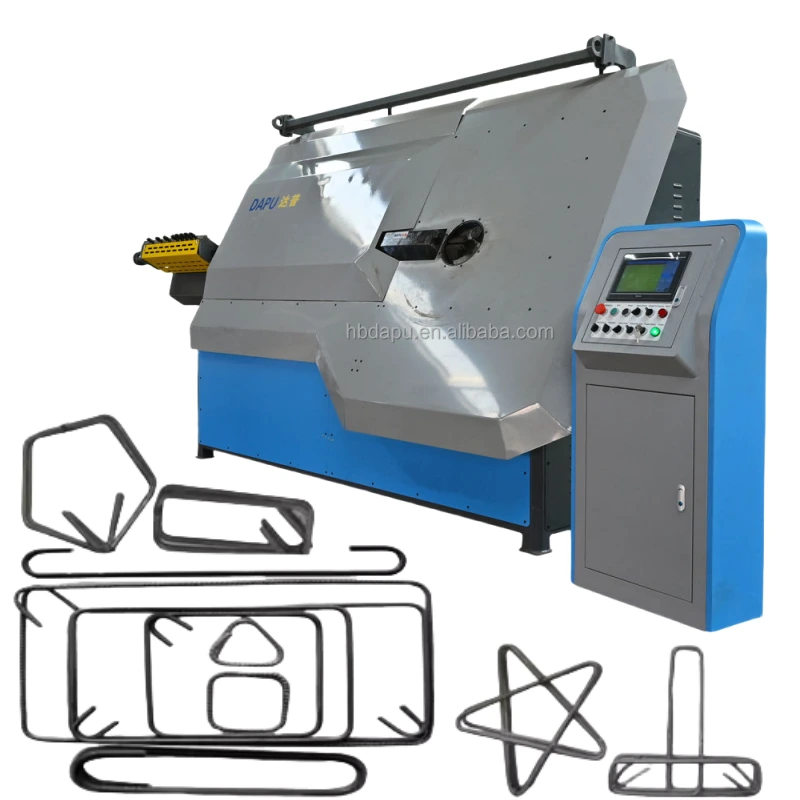

Dapu Automatic Steel Wire Rebar Stirrup Bending Machine Concrete Structure Use Automatic Reinforcing Bender

Rebar stirrup bending machine

|

Model |

ZGW-16B |

|

|

Wire diameter range |

Single line |

Φ6-Φ16mm |

|

Double line |

Φ6-Φ12mm |

|

|

Traction speed |

Max.80-120m/min |

|

|

Bending speed |

1150°/sec |

|

|

Angle error |

+/-1° |

|

|

Length error |

+/-1mm |

|

|

Min.bending length |

100mm |

|

|

Bending angle |

Max.180° |

|

|

Air pressure |

≥0.8Mpa |

|

|

Total Power |

34kw |

|

|

Electricity consumption |

7kw/h |

|

|

Dimension |

11970*2700*2950 |

|

|

Weight |

4000kg |

|

The machine can finish straightening, length fixing, bending, cutting automatically, continuously produce any planar shapes. It is widely used in construction, steel plants and railway, highway, water conservancy construction, nuclear facilities etc.

1.The machine adopts PLC + touch screen control, very easy to operate. It can store more than 100 bending shapes.

2.The wire feeding part is controlled by 4 traction rollers (High hardness alloy steel material) and servo motor, can make the wire move forward and backward, set the wire length.

3.The straightening part adopt 12pcs per-straightening rollers and 14pcs straightening rollers. The direction is perpendicular, guarantee output wire straight.

4.The bending part is controlled by servo motor, guarantee bending precision.

5.The cutting part is mechanical type, speed is higher.

6. Finished wire receiving shelf 12m length.

|

PLC+touch screen control |

|

|

|

|

|

wire feeding part |

Finished wire receiving shelf |

|

|

|

|

straightening part |

|

|

|

|

|

Bending part and cutting part |

|

|

|

|

1. Can you make the English language or other language of the CNC control system for the customers?

Yes. Of course. We can make different language for the cnc control. Just tell us which language you need .

2. Can you change the machine's color for the customers?

Yes. We can customize the color as what you want;

3. What is the delivery time?

If we have machines in stock, delivery time with 3-5 days. If we don't have the stock,the delivery time is 7-10 days;

4.How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone,online chat (Facebook, Skype,Whatsapp,Wechat). Please contact us once the machine has any problem. Best service will be offered.

5 .What certification do you have?

All of our machines have the CE and ISO certificate which ensures the quality and safety.